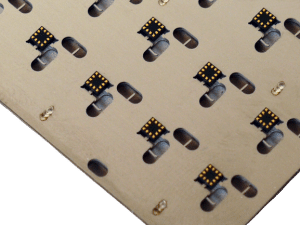

InCarrier

Solution for Test-in-Strip

The InCarrier process is based on a strip-like device carrier for single devices that combines the advantages of the singulated device test with the advantages of high parallel strip test. Leveraging the strip like design the InCarrier ensures robust test-handling for even smallest devices and supports high parallel test.

The InCarrier material flow at the test floor remains over all similar to the established standard process. Unlike strip test, the InCarrier test requires no singulation after test. Therefore the final test remains true final test. This way it overcomes the boundaries of strip test and meets the automotive 6 sigma – 0 PPM requirements.